How to Adjust Air Compressor Pressure Switch Control Valve

If you’re the proud owner of an air compressor, you know how invaluable it can be for a wide range of projects, from inflating tires to powering pneumatic tools. However, to ensure your air compressor operates at peak efficiency, it’s crucial to properly adjust the pressure switch control valve. This often-overlooked component plays a vital role in regulating the air pressure within your system, and getting it just right can make all the difference.

In this comprehensive guide, we’ll dive deep into the world of air compressor pressure switch control valves, exploring the ins and outs of proper adjustment. Whether you’re a seasoned DIYer or a newcomer to the world of air compressors, you’ll find the information you need to keep your machine running like a well-oiled (or pressurized) machine.

Table of Contents

Understanding the Pressure Switch Control Valve

The pressure switch control valve is the unsung hero of your air compressor’s operation. This nifty little component is responsible for monitoring the air pressure within the system and turning the compressor on and off as needed to maintain the desired pressure range.

When the air pressure in the tank drops below a certain level, the pressure switch control valve signals the compressor to kick on and refill the tank. Conversely, when the pressure reaches the upper limit, the valve tells the compressor to shut off, preventing the system from becoming overpressurized.

Proper adjustment of this valve is critical to ensuring your air compressor operates safely and efficiently. If the pressure switch is set too high, the compressor will cycle on and off more frequently, which can lead to premature wear and tear on the motor. Conversely, if the pressure is set too low, the compressor may not be able to build up enough pressure to power your tools effectively.

Tools and Materials Needed

Before you dive in, make sure you have the following tools and materials on hand:

- Adjustable wrench or pliers

- Pressure gauge

- Owner’s manual (if available)

Step-by-Step Guide to Adjusting the Pressure Switch Control Valve

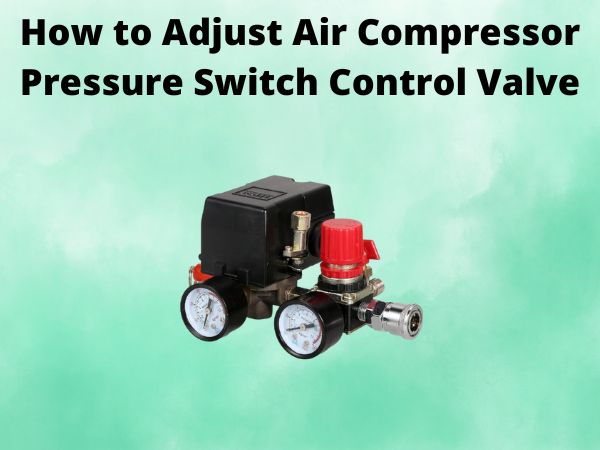

1. Identify the Pressure Switch Control Valve

The first step is to locate the pressure switch control valve on your air compressor. This component is usually located near the tank, often on the side or top of the unit. It may be labeled with the words “pressure switch” or “control valve,” or you may need to consult your owner’s manual to pinpoint its exact location.

2. Disconnect the Power

For safety’s sake, make sure to unplug your air compressor or disconnect it from the power source before attempting any adjustments. This will prevent the compressor from accidentally starting up while you’re working on it.

3. Attach the Pressure Gauge

Next, you’ll need to attach a pressure gauge to the air compressor’s output port or tank. This will allow you to monitor the pressure levels as you make adjustments to the control valve.

4. Locate the Adjustment Screw

On the pressure switch control valve, you should see a small adjustment screw or nut. This is the component you’ll be manipulating to change the pressure settings.

5. Adjust the Pressure

With the pressure gauge in place, you can now begin adjusting the pressure switch control valve. Turning the adjustment screw clockwise will increase the pressure, while turning it counterclockwise will decrease the pressure.

Start by turning the screw a quarter-turn at a time, and then check the pressure gauge to see how the settings have changed. Continue adjusting until the pressure reaches the desired range, as specified in your air compressor’s owner’s manual.

6. Test the Adjustment

Once you’ve made your adjustments, it’s time to test the pressure switch control valve to ensure it’s functioning properly. Turn the power back on and allow the compressor to cycle through a few pressurization and depressurization cycles, checking the pressure gauge each time.

If the pressure is consistently within the recommended range, you’ve successfully adjusted the control valve. If not, you may need to make some additional fine-tuning adjustments until you achieve the perfect pressure settings.

Conclusion

Adjusting the pressure switch control valve on your air compressor may seem like a daunting task, but with the right tools and a bit of know-how, it’s a relatively straightforward process. By taking the time to ensure your control valve is properly calibrated, you can enjoy the benefits of a well-functioning air compressor for years to come.

FAQs

How do I know if my air compressor pressure switch needs adjusting?

If you notice that your air compressor is cycling on and off more frequently than usual, or if the pressure in the tank seems to be fluctuating widely, it may be time to adjust the pressure switch control valve.

What is the ideal pressure range for my air compressor?

The ideal pressure range for your air compressor will depend on the specific model and its intended use. Consult your owner’s manual or the manufacturer’s recommendations to determine the optimal pressure settings for your particular unit.

Can I adjust the pressure switch while the compressor is running?

No, it’s crucial to disconnect the power source before attempting any adjustments to the pressure switch control valve. Working on a live air compressor can be extremely dangerous, so always make sure the unit is powered off before making any changes.

How often should I check and adjust the pressure switch?

As a general rule, it’s a good idea to check and adjust the pressure switch control valve on your air compressor at least once a year, or whenever you notice any changes in its performance. Regular maintenance will help ensure your air compressor continues to operate safely and efficiently for years to come.

What should I do if I can’t get the pressure switch to adjust properly?

If you’ve followed all the steps and are still unable to get the pressure switch control valve adjusted to the desired range, it’s possible that the component is faulty and needs to be replaced. In this case, it’s best to consult a professional air compressor technician for further assistance.