How to Adjust the Cut-In Pressure on Your Air Compressor

If you’re like me, you rely on your trusty air compressor to power a variety of tools and equipment around the home or workshop. But have you ever noticed that your air compressor doesn’t always kick on when you need it to? This could be a sign that the cut-in pressure needs to be adjusted. In this comprehensive guide, I’ll walk you through the step-by-step process of adjusting the cut-in pressure on your air compressor, so you can keep your projects running smoothly.

Table of Contents

What is Cut-In Pressure?

Before we dive into the adjustment process, let’s first understand what cut-in pressure is and why it’s important. The cut-in pressure is the minimum air pressure at which your air compressor will automatically turn on and begin refilling the air tank. This is a critical setting because it determines when your compressor will kick in to maintain the desired air pressure in the tank.

If the cut-in pressure is set too high, your compressor may not turn on until the tank pressure drops significantly, leaving you without the air pressure you need to power your tools. Conversely, if the cut-in pressure is set too low, your compressor will be running more frequently than necessary, wasting energy and potentially wearing down the components sooner.

Why Adjust the Cut-In Pressure?

There are several reasons why you might need to adjust the cut-in pressure on your air compressor:

- Changing tool requirements: If you’re using different tools or equipment that require varying air pressure, you may need to adjust the cut-in pressure to ensure your compressor is providing the right amount of air.

- Efficiency and performance: Optimizing the cut-in pressure can help your compressor run more efficiently, reducing energy consumption and extending the lifespan of the components.

- Troubleshooting issues: If your air compressor is cycling on and off more frequently than it should, or if it’s not providing enough air pressure, adjusting the cut-in pressure may be the solution.

How to Adjust the Cut-In Pressure

Now, let’s get to the good stuff – the step-by-step process for adjusting the cut-in pressure on your air compressor. Here’s what you’ll need to do:

1. Locate the Cut-In Pressure Adjustment

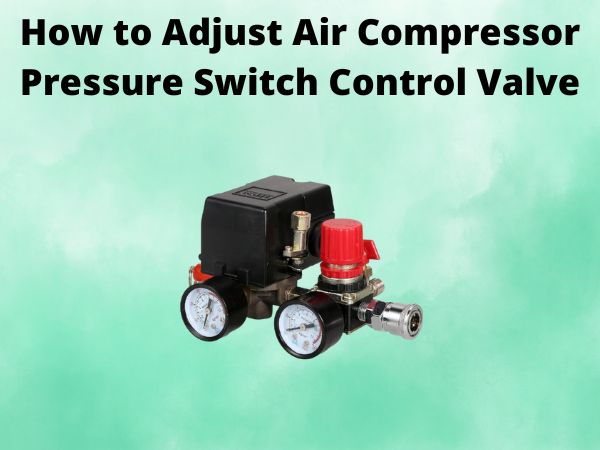

The first step is to locate the cut-in pressure adjustment on your air compressor. This is typically a knob, dial, or screw that’s located near the pressure switch or the air tank. Consult your owner’s manual if you’re unsure where to find it.

2. Determine the Current Cut-In Pressure

With the air compressor running, use a pressure gauge to measure the current cut-in pressure. This will give you a baseline to work from as you make adjustments.

3. Adjust the Cut-In Pressure

Depending on your air compressor model, you may need to turn the adjustment knob or screw clockwise to increase the cut-in pressure, or counterclockwise to decrease it. Make small adjustments, and then check the pressure gauge to see the results.

4. Test the Adjustment

Once you’ve made the adjustment, let the air compressor cycle a few times to ensure the new cut-in pressure is working as intended. If the compressor is still turning on too early or too late, repeat the adjustment process until you achieve the desired result.

Conclusion

Adjusting the cut-in pressure on your air compressor is a simple yet essential maintenance task that can help you keep your tools and equipment running at their best. By following the steps outlined in this guide, you’ll be able to fine-tune your compressor’s performance, improve efficiency, and extend the life of your valuable equipment. So don’t hesitate to give it a try – your air compressor will thank you!

FAQs

How do I know if I need to adjust the cut-in pressure?

You may need to adjust the cut-in pressure if your air compressor is cycling on and off more frequently than it should, if it’s not providing enough air pressure, or if you’re using different tools that require varying air pressure levels.

What is the optimal cut-in pressure for an air compressor?

The optimal cut-in pressure for an air compressor can vary depending on the specific model and the tools or equipment you’re using. As a general guideline, most air compressors should have a cut-in pressure between 90-120 PSI.

Can I adjust the cut-in pressure on any air compressor?

Yes, the ability to adjust the cut-in pressure is a common feature on most air compressors, regardless of the size or power. However, the specific adjustment process may vary depending on the model, so be sure to consult your owner’s manual for detailed instructions.

How often should I adjust the cut-in pressure?

There’s no set rule for how often you should adjust the cut-in pressure, as it can depend on factors like the frequency of use, the types of tools you’re using, and any changes in your compressor’s performance. As a general guideline, it’s a good idea to check and adjust the cut-in pressure every few months, or anytime you notice a change in your compressor’s behavior.

What happens if I don’t adjust the cut-in pressure?

If you don’t adjust the cut-in pressure on your air compressor, it can lead to a few issues, such as reduced efficiency, increased energy consumption, and potentially shorter lifespan for the compressor’s components. Regularly adjusting the cut-in pressure helps ensure your air compressor is operating at its best and providing the right amount of air pressure for your needs.